EnStyro Styrofoam Recycling

Info@EnStyro.com

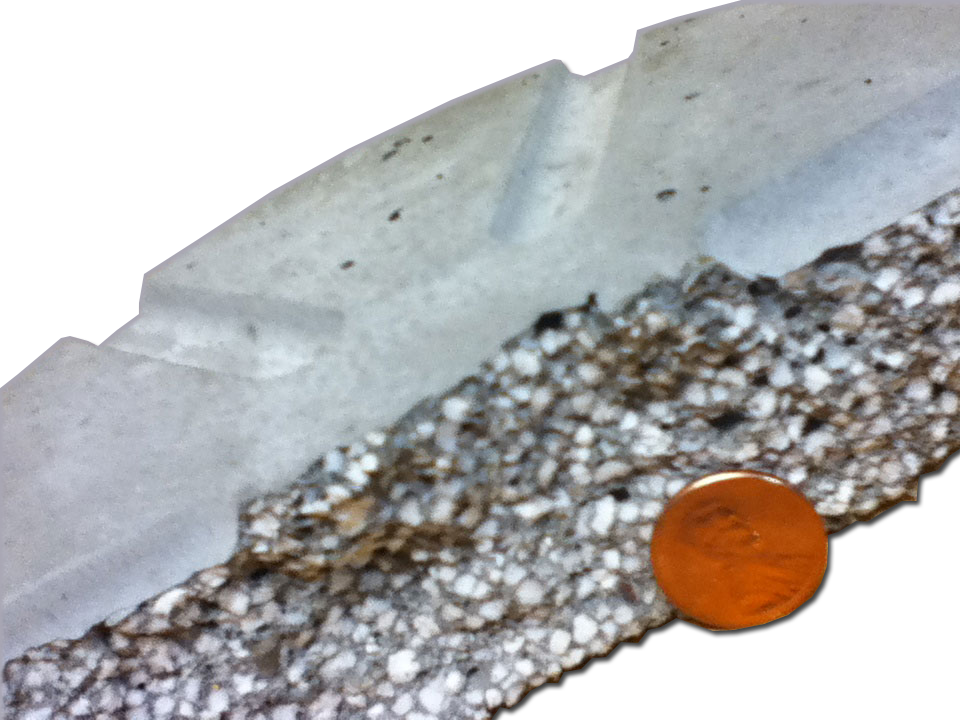

Enstyro Shred

Concrete Aggregate

Styrofoam has been around for over fifty years, why isn’t it used in concrete now?

EPS (Styrofoam) has been used in concrete. New EPS beads are currently sold as concrete aggregate, and several universities have studied shredded recycled foam as concrete aggregate. Both methods are only slightly successful for very different reasons.

EPS (Styrofoam) has been used in concrete. New EPS beads are currently sold as concrete aggregate, and several universities have studied shredded recycled foam as concrete aggregate. Both methods are only slightly successful for very different reasons.

New beads are round and smooth which is the worst shape and surface for a concrete aggregate. When just a little too much water is added to the mix, the bubble shaped beads float toward the top and ruin a job. Contractors that have to tear down a new job because this happens refuse to try EPS ever again. New beads and word of mouth have given EPS a bad name in concrete.

Shredded EPS has failed to catch on for a very different reason. It doesn’t float to the top because it has plenty of surface roughness. It does however include very small particles which, being torn up foam, have an enormous amount of surface area. This massive amount of surface area from the finest particles requires too much water to make concrete flow well and cure quickly. Too much water reduces compression strength in concrete.

Enstyro equipment solves the problems by shredding to a precise size range and then removing the very finest particles in one easy step. This method gives the surface roughness and shape variation to resist floating out even when thoroughly vibrated. Removing the smallest particles makes for easy mix design. Wet cement that flows easily and achieves high strength is now together with recycled EPS.

Enstyro Shred is truly the best of all worlds when it comes to EPS aggregate. If you have tried EPS in the past, please give it another chance. Enstyro has spent a lot of time to get it right and now everyone can reap the rewards of insulating crack resistant concrete.